What Is a Sleeved Plug Control Valve?

A sleeved plug control valve is a type of rotary valve where a tapered or cylindrical plug rotates inside a PTFE-lined or elastomer-lined body. The plug contains a passage that aligns with the ports of the valve body to regulate flow. What sets this valve apart is the soft sleeve usually made of PTFE or PFA that envelopes the plug and offers superior sealing and chemical resistance.

Key Components:

- Plug: Cylindrical or tapered, controls the flow path

- Sleeve: A replaceable soft lining (often PTFE) that provides sealing and protects from corrosive fluids

- Valve Body: Available in a range of materials, typically lined with PFA or PTFE

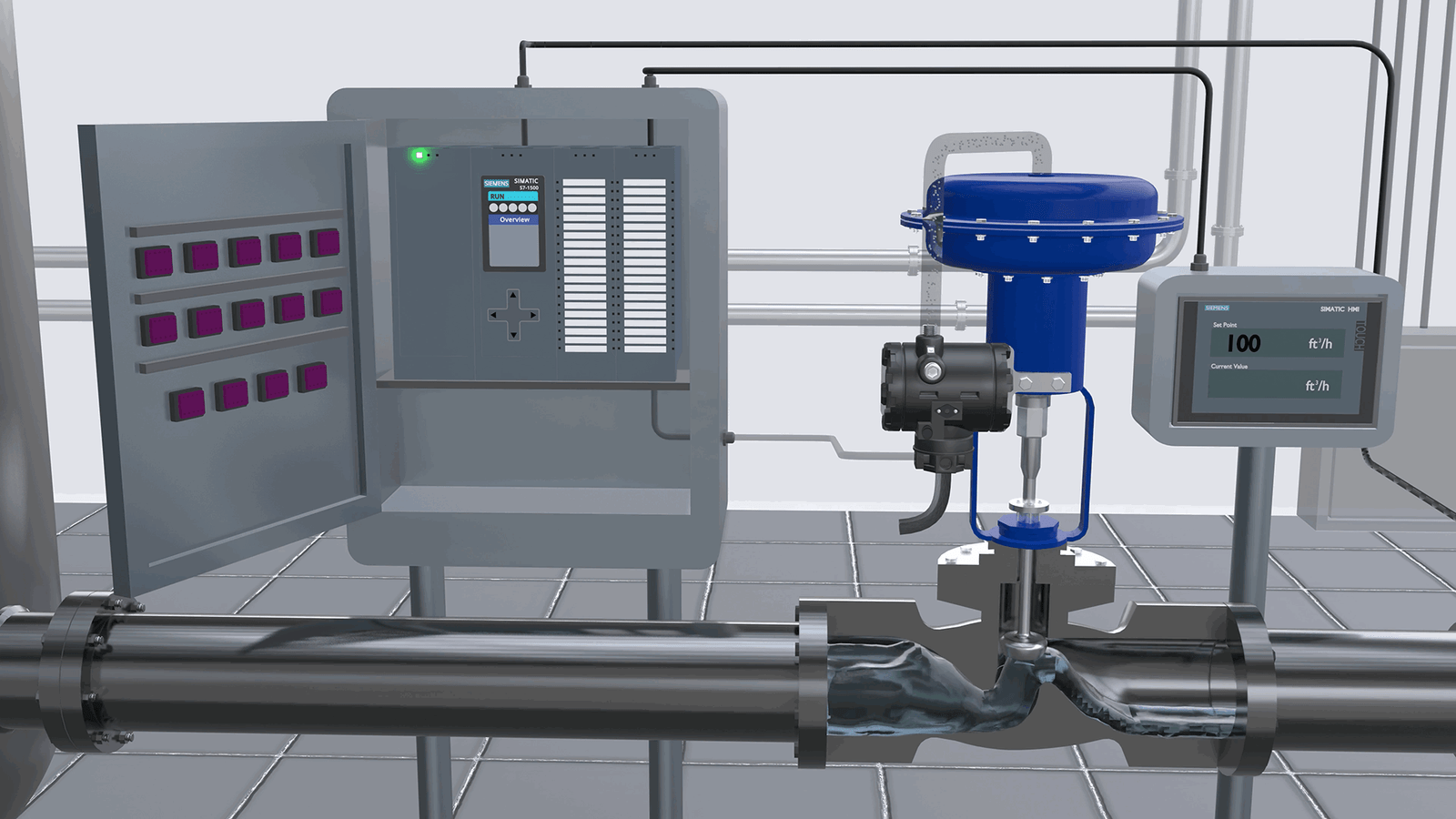

- Actuator: Manual, pneumatic, or electric for automated control

Benefits of Sleeved Plug Control Valves

1. Unmatched Corrosion Resistance

The use of PFA or PTFE lining in the sleeve and body ensures the valve withstands highly corrosive media like acids, alkalis, and solvents. Unlike metal-seated valves, PTFE lined valves don’t suffer from chemical pitting or corrosion.

2. Superior Sealing Performance

The double-sealed design using a sleeve provides tight shut-off capabilities, even in challenging environments. These valves are bubble-tight and reduce fugitive emissions, making them compliant with environmental regulations.

3. Minimal Maintenance

Since the internal components are fully protected by the sleeve, wear and tear are minimized. The sleeve also acts as a self-lubricating element, reducing operational torque and maintenance downtime.

4. Resistant to Abrasion

Abrasive fluids like slurry, pulp, or granulated chemicals can quickly degrade conventional valve types. The sleeved plug control valve’s plug rotation minimizes direct wear on the body, making it highly resistant to abrasion.

5. Reliable in High-Cycle Applications

The rotary motion and durable sleeve enable the sleeved plug valve to handle thousands of cycles without losing performance, making it ideal for continuous process control.

6. Versatility in Media Handling

Whether you’re controlling steam, slurry, gas, or corrosive chemicals, sleeved plug control valves offer broad compatibility, thanks to fully PFA lined internals.

Typical Industrial Applications

- Chemical Processing

- For acids, bases, and organic solvents, sleeved plug control valves deliver reliable shut-off and control.

- Their PTFE lined interior ensures compatibility with a wide pH range.

- Pharmaceutical and Biotech

- Cleanroom-compatible materials and non-stick PTFE surfaces help maintain process purity.

- CIP (Clean-in-Place) support is an added advantage.

- Mining and Mineral Processing

- Handles abrasive slurries with long service life.

- Resistant to scale and particle buildup.

- Power Plants

- Ideal for cooling water, chemical injection, and waste stream isolation.

- Resistant to thermal cycling and scaling.

- Pulp and Paper

- Controls thick stock and fibrous fluids without clogging or excessive wear.

- Water and Wastewater Treatment

- Withstands corrosive wastewater and sludge.

- Easy to operate in high-pressure environments.

Materials and Lining Options

The performance of a sleeved plug valve heavily depends on the lining material. DJK Valves & Pumps offers custom options based on application.

Common Lining Materials:

- PTFE (Polytetrafluoroethylene): Chemically inert, handles -29°C to 200°C

- PFA (Perfluoroalkoxy Alkane): Higher temperature and chemical resistance

- FEP (Fluorinated Ethylene Propylene): Transparent, lower cost, good chemical resistance

- UHMWPE (Ultra High Molecular Weight Polyethylene): Abrasion-resistant

Customization and Actuation

Sleeved plug control valves are highly customizable:

- End Connections: Flanged, threaded, or butt-welded

- Sizes: DN15 to DN600 and beyond

- Actuation: Manual lever, gear-operated, pneumatic, or electric actuator

- Accessories: Limit switches, positioners, solenoids, and feedback devices

Actuated sleeved plug valves are ideal for integration into process automation systems, enabling real-time flow modulation.

Standards & Certifications

Reliable manufacturers such as DJK Valves & Pumps ensure compliance with international standards:

- API 599 / 6D

- ASME B16.34

- ISO 15848 (Fugitive Emissions)

- ATEX (Explosive Environments)

- Fire-safe design (optional)

DJK Sleeved Plug Control Valves – Engineered for Performance

DJK’s range of sleeved plug control valves is designed to meet the most rigorous industrial requirements. With fully PFA lined bodies, bubble-tight shutoff, and custom actuator options, our valves are used worldwide in critical applications.

Available Models:

- Series 50 Sleeved Plug Valve – Standard corrosive service

- Series 51 Actuated Plug Valve – For automation and control loops

- Series 52 Fire-Safe Design – For hazardous environments

- Series 53 Jacketed Body – For temperature-sensitive fluids

Conclusion

When it comes to managing corrosive and abrasive fluids, the sleeved plug control valve remains unmatched. Its combination of chemical resistance, durability, low maintenance, and precision control makes it an indispensable asset across industries.Whether you’re upgrading your existing setup or designing a new process line, consider PTFE or PFA lined sleeved plug valves for safer, longer-lasting, and efficient performance.

Know more about our ProductLlines.