As industrial automation continues to evolve, the role of control valves in process systems has become increasingly critical. At DJK Valves & Pumps, a trusted manufacturer of industrial valve solutions, we are proud to share in-depth knowledge on control valves, their types, applications, components, and accessories helping you make informed decisions for your process needs.

What Is a Control Valve?

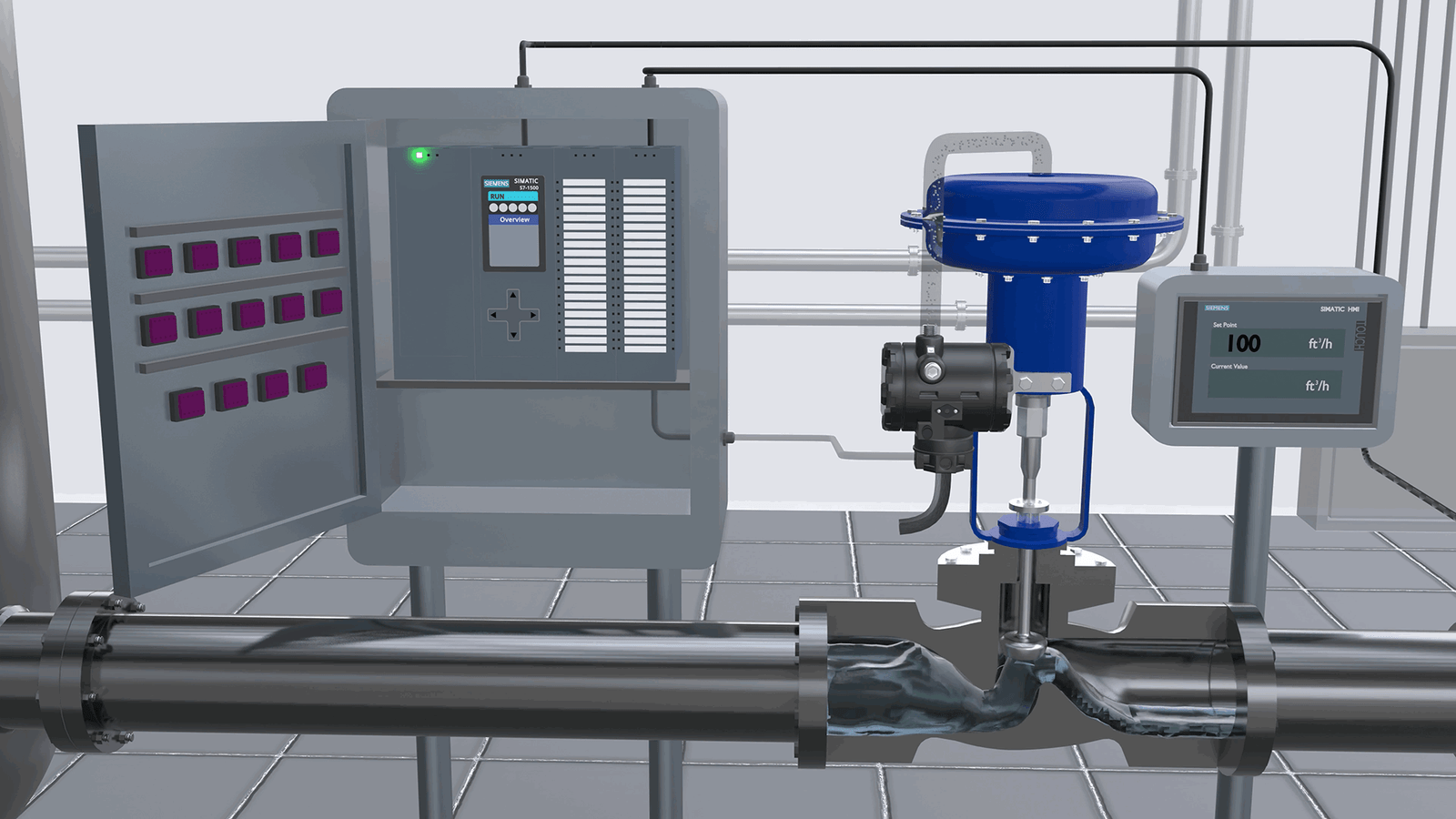

A control valve is a mechanical device used to regulate fluid flow, pressure, temperature, or level within a process system. In a typical industrial control loop, the control valve acts as the final control element, receiving signals from a controller to open or close based on process variables like pressure, flow rate, or temperature.

DJK control valves are widely utilized in oil & gas, chemical processing, power generation, water treatment, pharmaceuticals, and steel & metallurgy industries. These valves are essential in ensuring efficient and accurate process control

How Control Valves Work in Process Loops

In a closed-loop control system, sensors and transmitters gather data (e.g., pressure, temperature, level), which is compared with setpoints in a controller. The controller sends a corrective signal to the control valve actuator, which adjusts the valve opening to maintain process stability.

Think of it like this:

- Sensor = Eyes

- Controller = Brain

- Control Valve = Hands

The control valve executes the necessary physical changes to keep process variables within the desired range.

Types of Control Valves by DJK Valves & Pumps

1. Globe Control Valve (Series 10)

- Precision control

- Linear motion

- Available as 2-way, 3-way mixing, and 3-way diverting valves

- Excellent shutoff and modulation accuracy

2. Butterfly Control Valves (Series 20 & Series 21)

- High Performance Butterfly Valves

- Triple Offset Butterfly Valves

- Ideal for large-diameter pipelines

- Low torque, fast actuation, tight shutoff

3. Ball Control Valves (Series 90)

- Segmented V-Port or Full Port Ball Valve

- Durable and cost-effective

- Great for moderate control applications

- Suitable for clean or slurry media

4. Sleeved Plug Control Valves

- PTFE/PFA lined options for corrosive and abrasive media

- Reliable sealing, excellent for chemical processing

- Low maintenance, high cycle life

5. Eccentric Plug Control Valve

- Combines globe and rotary valve benefits

- Low-friction operation

- Ideal for slurry, high-pressure, and dirty fluid applications

Valve Components by DJK

Linear Control Valves (Globe Type)

- Body: Handles pressure and fluid direction

- Bonnet: Protects stem and internal components

- Trim: Includes stem, plug, and seat

- Ideal for precise control with low leakage

Rotary Control Valves (Ball, Butterfly, Plug)

- Body & Integral Bonnet: One-piece design

- Disc/Ball/Plug: Closure elements

- Shaft or Stem: Transfers motion from actuator

Control Valve Accessories

1. Actuators

- Pneumatic Actuators (Diaphragm, Piston, Rotary)

- Electric Actuators (Linear and Rotary)

- Choose based on power source, fail-safe requirements, precision, and site conditions

2. Valve Positioners

- Smart Positioners, Electro-Pneumatic, or Digital

- Improve control accuracy by modulating actuator based on position feedback

3. Limit Switches

- Provide open/close position feedback to PLC/DCS systems

4. Solenoid Valves

- Vent air or lock the actuator for safe shutdowns

5. Lockup Valves & Quick Exhaust Valves

- Essential for fail-safe operation

6. Volume Boosters & I/P Transducers

- Boost actuator speed and convert electrical signals to pneumatic signals

7. Air Filter Regulator

- Ensures clean and regulated air pressure to pneumatic actuators

8. Manual Override

- Allows manual operation in emergencies using handwheel or gear mechanisms

Important Control Valve Terminology

Cv (Flow Coefficient)

Defines how much flow a valve can pass. Higher Cv = greater flow.

Seat Leakage (ANSI/FCI 70-2)

Class I to VI ratings indicate permissible leakage levels. DJK valves offer Class IV+ tightness.

Flow Characteristics

- Equal Percentage (EQ%)

- Linear

- Quick Opening

Each DJK valve type offers characteristic curves based on trim and actuator pairing.

Cavitation Risk & Control Valve Selection

High-velocity flows and large pressure drops can lead to cavitation. DJK’s control valves, especially globe and eccentric plug designs, offer anti-cavitation trims and noise reduction solutions.

Why Choose DJK Valves & Pumps?

At DJK Valves & Pumps, we offer a complete portfolio of control valves, PFA/PTFE lined valves, and actuated valve solutions for every application:

- Globe Control Valves (Series 10, 10C Cryogenic, Series 11 High Pressure)

- Butterfly Control Valves (Series 20 & 21 Triple Offset)

- Ball Valves, Plug Valves, and Sleeved Plug Valves

- Pressure Relief Valves & Tank Protection Devices

- Automated Actuation Systems with Positioners, Limit Switches, and Accessories

All DJK products are engineered for chemical resistance, tight shutoff, reliable control, and cost-effective performance.

We specialize in tailored valve solutions for corrosive, high-pressure, abrasive, and temperature-sensitive applications across oil & gas, chemical plants, pharma, and power generation.

Conclusion

Understanding control valves from types to actuators and accessories is essential to optimizing your industrial process. DJK Valves & Pumps delivers trusted, tested, and tailored valve solutions to meet your most demanding operational needs. For expert support in selecting the right flow control valve, automated control valve, or PFA lined control solution, trust DJK Your Partner in Precision Flow Control.