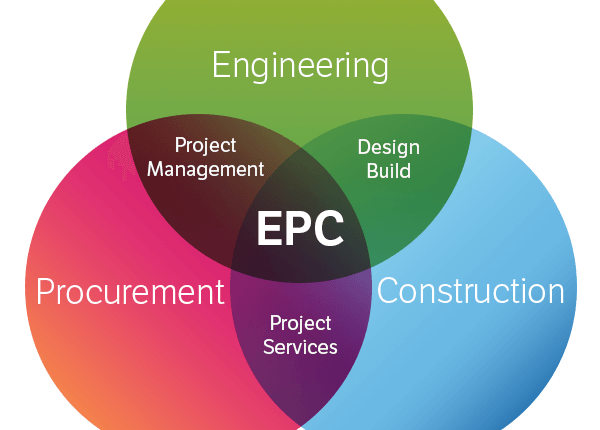

In large-scale industrial and infrastructure developments such as power plants, chemical facilities, and manufacturing plants the need for a seamless, end-to-end project execution approach is vital. This is where Engineering, Procurement, and Construction (EPC) contractors come in.

An EPC contract is a turnkey arrangement where a single contractor is responsible for the entire project lifecycle from initial design and engineering, through the procurement of materials and equipment, to final construction and commissioning. This model offers project owners a single point of accountability, streamlined execution, and greater control over cost and timelines.

In this article, DJK Valves & Pumps explores the core responsibilities of EPC contractors, their advantages and limitations, and key considerations when choosing the right EPC partner for your industrial project.

What Is an EPC Contract?

An EPC contract is a comprehensive construction agreement commonly used in complex infrastructure projects, often referred to as “turnkey contracts.” Under this model, the EPC contractor is accountable for all phases of the project from design and procurement to construction and handover delivering a fully functional facility by a specified completion date.

This turnkey approach shifts significant risk from the project owner to the contractor, who is obligated to meet fixed performance, budget, and timeline targets. EPC contracts are commonly used in sectors like oil & gas, power generation, chemical processing, and large-scale industrial facilities.

What an EPC Contractor Does

An EPC contractor is entrusted with managing the full scope of a construction project under a single contract. Their duties span:

- Engineering: Complete system design, layout, and technical schematics.

- Procurement: Acquisition and logistics of all required materials, equipment, and services.

- Construction: On-site building, installation, testing, and commissioning of the facility.

The EPC model ensures that the project is delivered in compliance with technical standards, within the predefined budget, and on schedule simplifying coordination and accountability for the owner.

Core Roles and Responsibilities of EPC Contractors

EPC contractors play a pivotal role in every stage of project development:

Concept & Planning

Initial ideation, brainstorming, and feasibility analysis to determine if the project is viable from technical and economic standpoints.

Front-End Engineering Design (FEED)

Detailed pre-construction design and planning, defining project scope, budgeting, and technical parameters to set the foundation for execution.

Engineering

Comprehensive design of civil, structural, electrical, and mechanical systems, tailored to industry standards and client requirements.

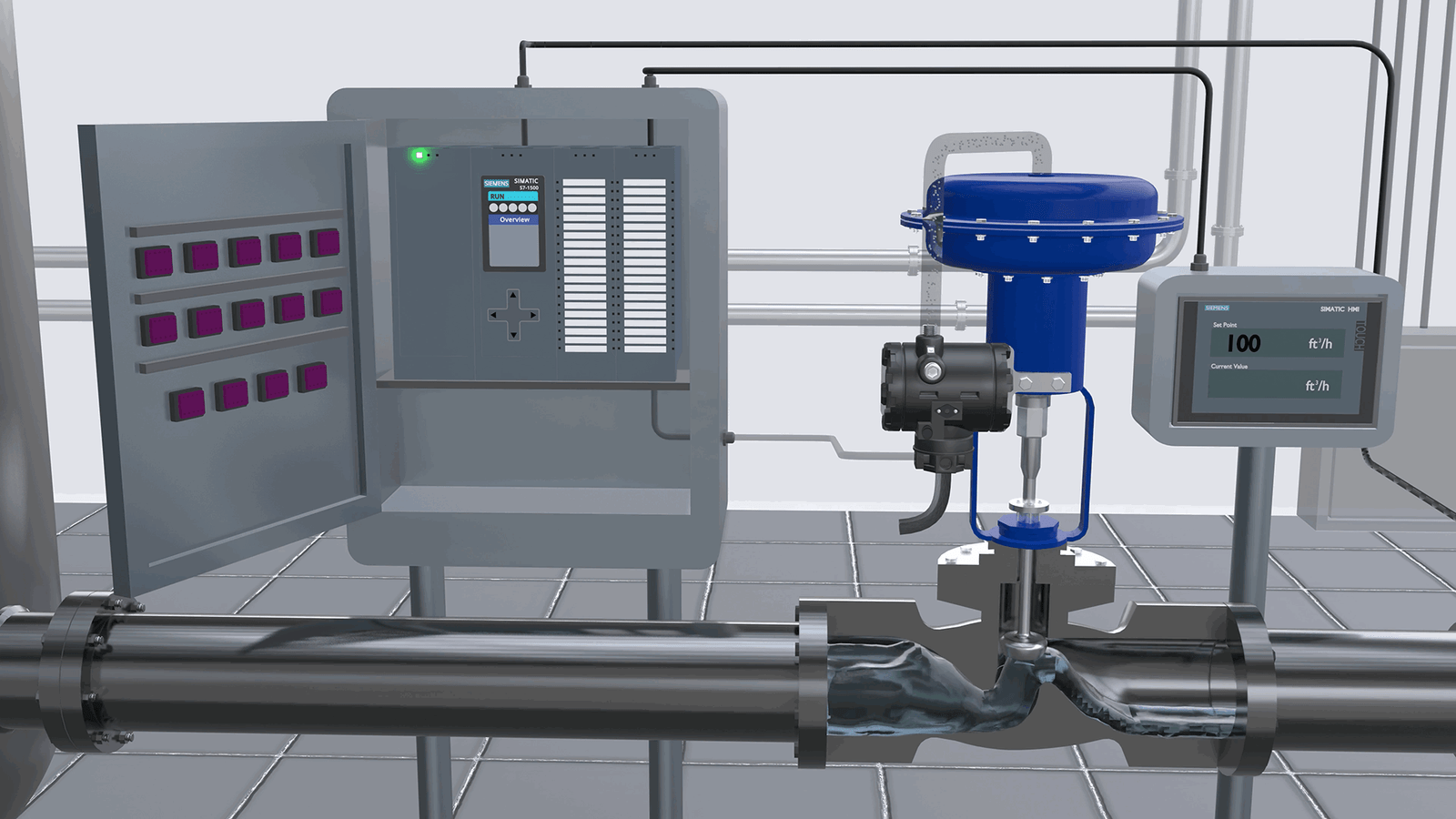

Procurement (This is where DJK Valves and Pumps comes into picture)

Sourcing and acquiring high-quality materials, valves, piping systems, instrumentation, and other equipment ensuring timely delivery and compliance with technical specifications.

At DJK Valves & Pumps, we support EPC contractors by supplying PFA/PTFE lined valves, control valves, and flow solutions engineered for reliability in harsh industrial environments. To know about our product lines, visit our website djkvalvespumps.com

Construction

Complete site mobilization and physical execution, including equipment installation, piping, structural erection, electrical works, and final finishing.

Commissioning & Handover

Testing and fine-tuning of systems to verify operational readiness, followed by official handover to the project owner with all documentation and compliance certificates.

Additional Responsibilities

Beyond their core scope, EPC contractors also handle:

- Risk Management

Mitigating cost overruns, delays, safety issues, and regulatory risks through proactive planning, safety protocols, and contingency strategies.

- Project Control & Reporting

Monitoring and tracking every aspect of project performance with transparent reporting tools and milestone-based evaluations.

- Change Management

Handling scope changes or modifications during execution in a structured and documented manner to avoid cost inflation or quality compromise.

Benefits of Using an EPC Contractor

Partnering with an EPC contractor for large-scale industrial projects offers several advantages:

Single Point of Accountability

All communication and project responsibility lie with one entity, simplifying coordination and decision-making.

Predictable Costs

EPC contracts are typically fixed-price, enabling better financial planning and reducing the risk of hidden costs.

Time Efficiency

With centralized planning and execution, EPC contractors reduce project delays and ensure timely completion.

Quality Assurance

Performance standards, material certifications, and process testing are all handled by the contractor to meet stringent industry benchmarks.

Risk Transfer

The contractor assumes most project risks, including price fluctuations, logistics challenges, and schedule overruns.

Flexible Execution

Despite the fixed-scope nature, EPC contracts often include built-in allowances for design evolution and external disruptions (e.g., force majeure clauses).

Limitations of EPC Contracts

While EPC models offer robust control and risk mitigation, there are also some drawbacks:

Limited Owner Flexibility

Once the contract is signed, making design or scope changes can be costly and complex.

Heavy Reliance on Contractor

If the EPC contractor fails to deliver on expectations whether due to financial instability or poor execution the entire project is jeopardized.

Premium Pricing

To account for assumed risks, contractors may include price buffers, leading to higher initial project costs.

Reduced Visibility

The owner has less daily oversight over construction activities, which could lead to misalignment if expectations aren’t well defined.

What to Look for in an EPC Contractor

Choosing the right EPC contractor is critical for project success. Consider the following factors:

- Proven Track Record in similar industries (chemical, power, water treatment)

- Financial Stability to ensure uninterrupted project execution

- Resource Capacity, including skilled labor, project managers, and equipment

- Safety Standards and certifications (ISO, OSHA, etc.)

- Strong Vendor Network, particularly for critical systems like control valves, lined piping, and automated process equipment

- Transparent Communication and robust project reporting systems

When to Work with an EPC Contractor

EPC contractors are best suited for:

- Projects requiring strict timeline and budget control

- Complex facilities with integrated mechanical, electrical, and process systems

- Environments where regulatory compliance and performance guarantees are essential

- Industrial developments where the owner wants to minimize risk and delegate execution

Examples include:

✅ Petrochemical plants

✅ Power generation stations

✅ Pharmaceutical manufacturing facilities

✅ Water and wastewater treatment systems

Conclusion

The EPC contract model offers a highly effective framework for delivering complex industrial and infrastructure projects. By integrating engineering, procurement, and construction under a single entity, EPC contractors streamline execution, provide cost and schedule certainty, and reduce overall project risks.

At DJK Valves & Pumps, we work closely with EPC contractors around the world by supplying high-performance industrial valves such as PFA lined valves, sleeved plug control valves, globe and butterfly valves, and custom flow control systems tailored for corrosive, high-pressure, and hazardous applications.

With the right EPC partner and trusted component suppliers, industrial projects can be completed with confidence, precision, and long-term reliability.

Know more about Product Line : Click Here