Control valves are essential components in modern process industries, responsible for directing, regulating, and managing the flow of gases, liquids, and slurries. Whether it’s pressure, temperature, or flow rate, control valves play a pivotal role in maintaining process stability and safety. From chemical processing to energy generation, industries in the United States rely heavily on advanced control valve technology to meet efficiency and compliance standards.

At DJK Valves & Pumps, our extensive range of Globe Control Valves, Angle Globe Valves, High Pressure Control Valves, Cryogenic, and Fully PFA Lined Control Valves caters to the complex needs of various U.S. sectors. This guide explores the key types and Series, including Series 10, Series 10C, Series 11, Series 20, Series 21, Sleeved Plug Control Valves, and Ball Control Valves (Series 90)

1. Globe & Angle Globe Control Valves

Globe Control Valves are widely recognized for their precise throttling capabilities and excellent shut-off performance. At DJK, the Series 10 Globe & Angle Control Valves offer reliable modulation for a wide range of flow conditions. These valves are designed with a linear motion stem and plug system that allows for accurate control of flow rates, even in variable load scenarios.

The Angle Globe Valve variant enhances this performance by providing a straight-through flow path with a 90-degree outlet. This design minimizes pressure loss and is particularly effective in applications involving high differential pressures. Industries across the United States, including oil & gas and chemical processing, prefer these for their durability and control accuracy.

For cryogenic applications, our Series 10C Globe & Angle Control Valves are engineered to perform in extremely low temperatures, making them ideal for LNG, oxygen, and nitrogen services. The extended bonnet design prevents frosting around actuators, ensuring long-term reliability in cryogenic systems.

To handle severe pressure environments, DJK’s Series 11 Globe & Angle Control Valves are designed for high-pressure applications and conform to ANSI Class 900 to 2500. These valves provide enhanced seat integrity, reduced fugitive emissions, and superior throttling for high-pressure steam, oil, and gas lines making them a go-to choice for energy plants across the U.S.

2. High-Performance & Triple-Offset Butterfly Valves

When compact design and responsive control are key, butterfly valves offer a high-performance alternative. The Series 20 High Performance Butterfly Valves from DJK are designed to provide excellent flow control with minimal pressure drop. These valves feature a double-offset design that reduces seat wear, making them highly efficient in modulating services.

For critical isolation in steam or hydrocarbon lines, the Series 21 Triple Offset Butterfly Valves offer a metal-to-metal seat design that ensures zero leakage performance. The triple offset geometry eliminates rubbing between the disc and seat, extending service life and maintaining tight shut-off.

Both valve types are extensively used in HVAC, refineries, power plants, and petrochemical industries throughout the United States, where tight shut-off, low torque, and high reliability are non-negotiable.

3. Sleeved Plug & Ball Control Valves

Sleeved Plug Control Valves are ideal for handling corrosive and abrasive media. DJK’s design features a fully encapsulated plug within a PTFE sleeve, ensuring low friction operation and bubble-tight shut-off. The plug design is free from cavities, which eliminates blockages from slurry or solids.

These valves are especially useful in wastewater treatment, chemical dosing, and mining applications where maintenance downtime is costly. Their low torque and long service life make them a top pick for U.S. industries focused on lifecycle value.

The Series 90 Ball Control Valves are rotary-type valves designed for modulating or on/off control. They provide a straight-through flow path with minimal pressure loss. The floating or trunnion-mounted design allows for accurate positioning and is suitable for pneumatic, natural gas, and utility systems.

Their compact design and high CV rating make them popular in the United States’ energy and petrochemical sectors, especially where space is a constraint.

4. Fully PFA-Lined Control Valves

In highly corrosive environments, valve longevity and purity are critical. Fully PFA Lined Control Valves from DJK provide the ultimate protection against aggressive chemicals. The PFA lining, chemically inert and heat-resistant, acts as a barrier between the process media and the valve body, extending service life significantly.

These PFA Lined Globe Control Valves are ideal for processes involving sulfuric acid, chlorine, or pharmaceutical ingredients. Whether integrated into a globe, butterfly, or plug valve body, the PFA lining ensures no metal contact with process fluid essential for FDA and EPA compliance in the United States.

Besides corrosion resistance, PFA-lined valves offer lower friction, resistance to thermal shock, and excellent surface finish minimizing contamination and material degradation.

5. High Pressure Control Valves

When working with high-pressure steam, gas, or hydraulic fluids, robust valve construction is non-negotiable. DJK’s Series 11 High Pressure Control Valves are specifically designed for such environments, offering ANSI Class ratings up to 2500. These valves are available in both globe and angle configurations and feature hardened trims, multi-stage cages, and noise attenuation designs.

Our High Pressure Control Valves are engineered to manage cavitation, pressure drops, and flashing. Multi-hole and anti-noise trims reduce turbulence and extend the life of both valve and piping.

These valves are commonly installed in boiler feed systems, compressor bypasses, and energy plants across the United States, where reliability under pressure is mission-critical.

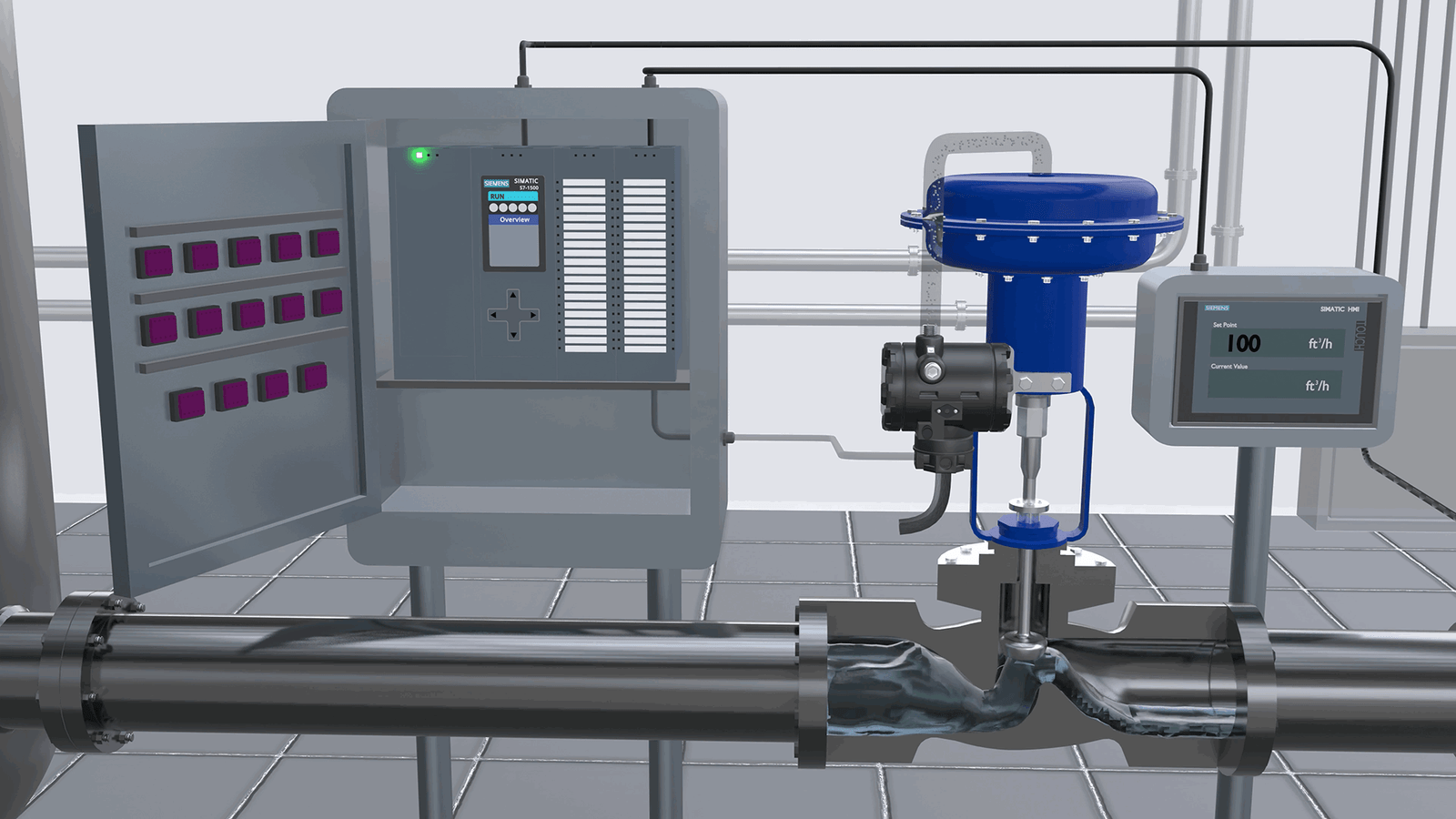

6. Accessories & Automation Pack

To support modern control systems, DJK also provides a complete range of control valve automation accessories:

- Series 30, 31, and 32 Pneumatic Actuators – Designed for fast, precise response and compact mounting.

- Electro-pneumatic positioners – Enable accurate control signal translation.

- Solenoid valves, I/P converters, and limit switches – For complete automation integration.

These accessories ensure our valves are plug-and-play with industry-leading DCS, SCADA, and PLC systems used in U.S. plants, supporting remote operation, diagnostics, and reduced manual intervention.

Conclusion

Choosing the right control valve is crucial for safe, efficient, and cost-effective industrial operations. Whether you’re managing pressure in a power plant or controlling flow in a chemical plant, DJK Valves & Pumps offers a complete portfolio from Series 10 Globe Valves to PFA Lined and High Pressure Control Valves designed for your U.S. application.

Looking for expert advice or a custom valve solution?

👉 Contact DJK Valves & Pumps for technical consultation or download detailed specifications from our Control & Automation Products page.